Description of the LSF SYSTEM (LIGHT STEEL FRAMING)

The Somundy “LSF” building system philosophy has been developed to carefully consider all steps of the construction process. We will describe our construction method; from the beginning when the foundation is poured to the completion, and the interior finish. Somundy Enterprise has thought of everything that concerns both builders and consumers.

What is "LSF"?

The “LSF” Light Steel Framing is a customized construction system known for being lightweight and advantageously adaptable to traditional construction systems, in which heavy machinery is not necessarily required for its installation.

The versatility of the material that corresponds to steel allows to adapt the engineering on any architectural project, which allows to integrate LSF components such as mezzanine trusses or slabs and decks that replace the use of other materials such as false ceilings that simplify the work in time and rationalization of materials that result in a light, resistant, safe and durable construction of high quality.

The LSF steel structure easily adapts to any form of finish on exterior and interior walls, mezzanines or slabs and roofs due to the flat and slender geometry of the supporting panels and trusses or beams that make up the superstructure where the substrates, waterproofing systems, thermal and acoustic systems, sanitary, ventilation and electrical systems are fixed and attached.

The steel used by somundy to manufacture an LSF superstructure is highly galvanized and resistant to wind and seismic conditions, adhering to international ASTM standards and AISI codes that guarantee that the cold-formed steel (Stud-track) meets the technical requirements and mechanical properties demanded in structural engineering.

The key to understanding the “LSF” is in the versatility of construction, flexibility, convenience for construction, saving energy, time and resources, as well as helping the environment by recycling 60% of galvanized steel.

Using LSF we have more than:

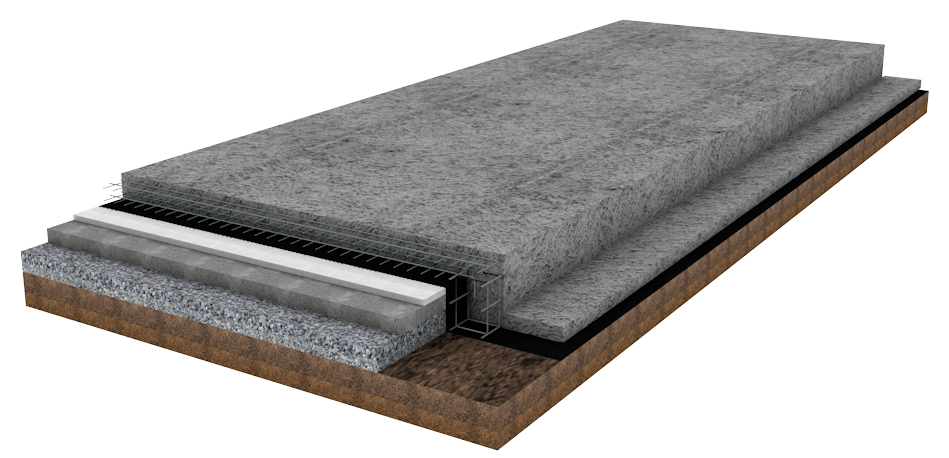

FOUNDATION

It corresponds to a reinforced concrete slab that extends over the entire surface of the construction, which will be the base where all the LSF structural elements will be implanted, such as: exterior load-bearing walls, light or interior load-bearing walls and other fastening elements and floor-structure connection.

ADVANTAGES:

– Economical, easy and fast to manufacture.

– Uniform distribution of building loads on the ground.

– Resistant to ground movements.

– It is sufficiently reinforced and does not require plinths.

MINIMUM CONDITIONS:

– The thickness of the slab must be at least 9-10cm reaching 14cm up to 2 floors in residential application (will depend on soil conditions and type of loads).

– The reinforcement of the foundation slab must have 1 electrowelded mesh and up to 2 depending on the structural stability calculation, as well as perimeter beams.

– The foundation slab must be level and square.

WALLS-PAREDS

The main function of Steel Framing load-bearing walls is to support the weight of the structures, live and dead loads, as well as the loads generated by earthquakes and winds. Its geometry is flat and the type of profile and channel to be used will depend on several factors such as: number of floors, wall-wall panels that meet the architectural requirements, geolocation, type of substrate to be supported, among others.

ADVANTAGES:

– Load-bearing panels that do not need to be fixed to a pillar.

– They are resistant and support all types of loads in general.

– Durable thanks to the type and quality of galvanized steel used in their design.

– Its composition and geometry gives it a cleaner visualization on site without corners or protrusions versus traditional construction.

– LSF wall-walls can be insulated to improve thermal and acoustic performance.

– They can be easily clad with various types of materials that are compatible by mechanical fastening (dry or wet).

– Cost reduction on site.

MINIMUM CONDITIONS:

– Profile displacements (Stud) every 60-61 cm in compliance with the standard, and every 40 cm depending on the applicability and by solicitation of the structural calculation.

– As it corresponds to load-bearing walls, the ideal is to maintain window and door spans no longer than 4 meters to avoid further reinforcement and to optimize the material in a better way.

– Ideally, lintels should have a minimum spacing of 20 cm.

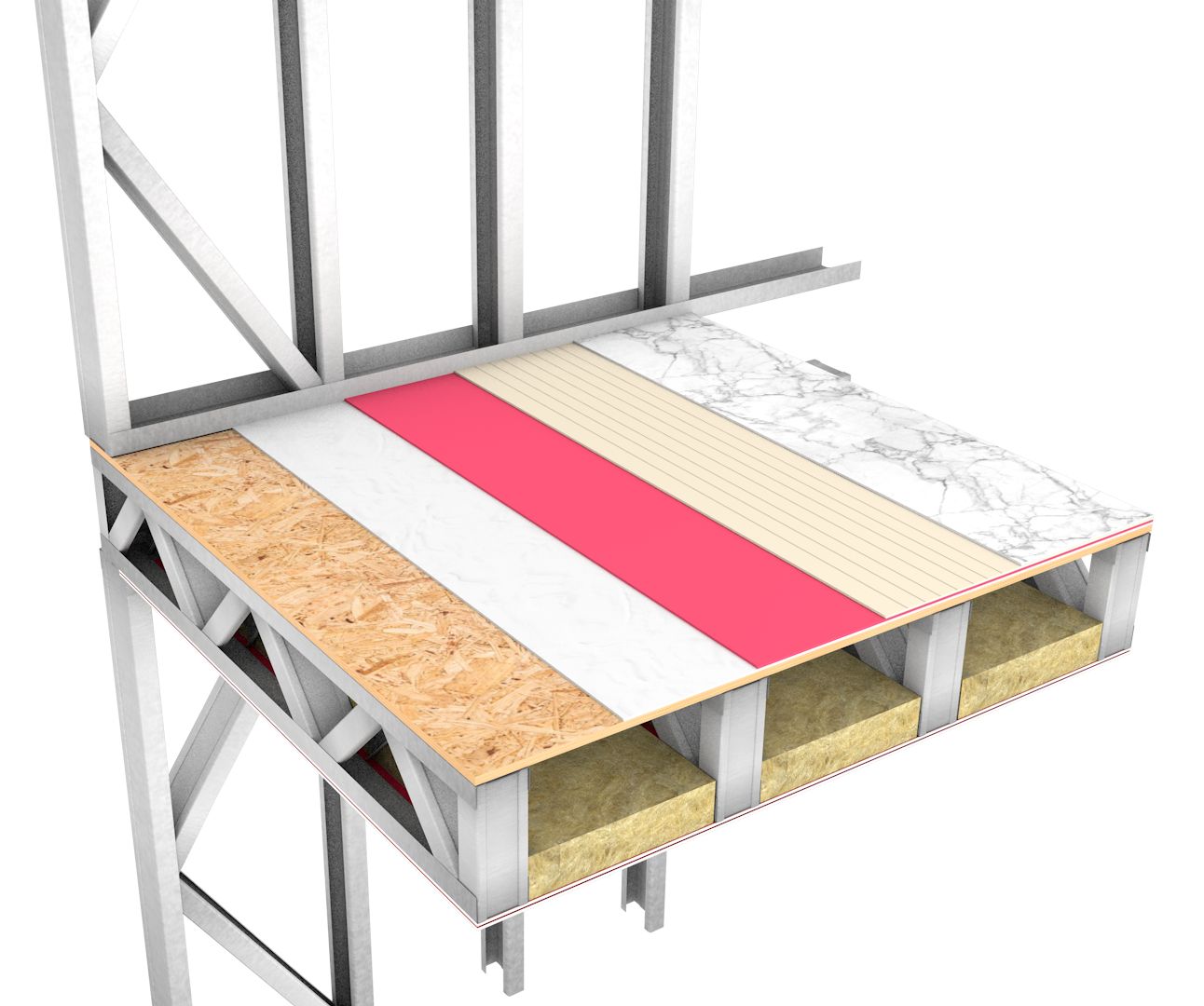

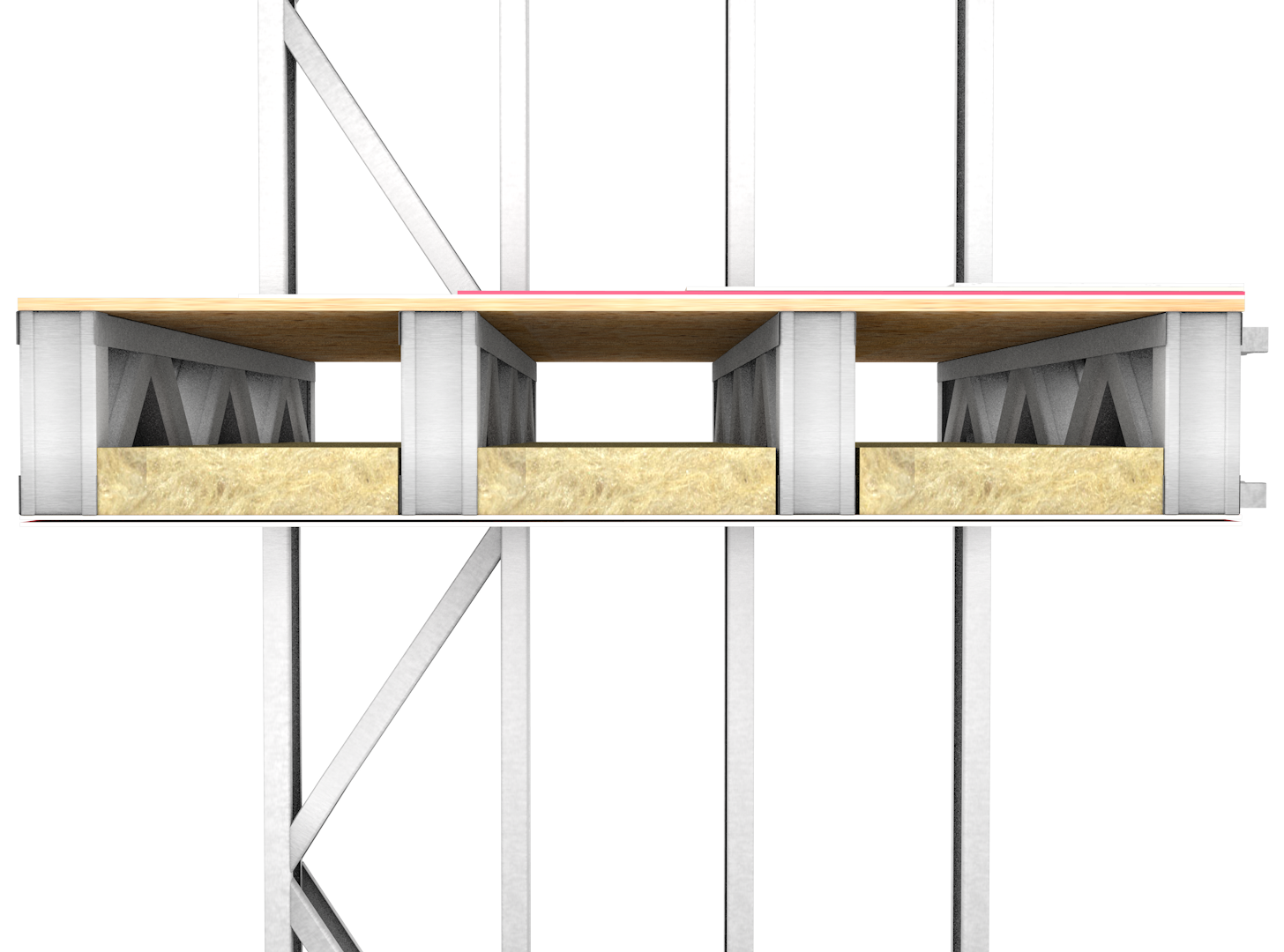

MEZZANINES OR FLOOR SLABS

The main function of the mezzanine floors or floors with beams or trusses modeled in Steel framing is to separate horizontally the different levels of a building becoming the floor of the upper level and ceiling of the interior level in order to support and distribute the loads evenly towards the walls-walls LSF.

ADVANTAGES:

– They are beams and trusses resistant to loads, light and with high durability.

– Adaptable to any geometry and architecture.

– The electrical and sanitary systems are easily integrated between trusses which generates time advantage on site.

– The ceiling of a mezzanine does not require false ceilings and the substrate can be fixed directly.

– LSF mezzanine floors can be insulated to improve thermal and acoustic performance.

– They can be easily covered by various types of materials that are compatible by mechanical fastening (dry or wet).

– Cost reduction on site.

MINIMUM CONDITIONS:

– Their design and geometry must guarantee resistance to gravity and lateral loads.

– Its distribution must respond to the distribution of the load-bearing walls.

– The dimensioning of the mezzanine must allow to adjust to the minimum required dimensions and comply with the requirements of the structural calculation.

COVERS

The main function of a roof with Steel framing beams or trusses is to enclose and protect the top level of the building.

ADVANTAGES:

– The LSF elements that make it up are divided equidistantly so that each one resists a portion of the total load of the structure.

– Adaptable to any geometry and architecture, it can be designed and manufactured as a flat or pitched roof.

– Electrical and pluvial systems are easily integrated between trusses and/or rafters, which generates a time advantage on site.

– A truss roof does not require false ceilings and the substrate can be fixed directly.

– LSF roofs can be insulated to improve thermal and acoustic performance.

– They can be easily clad with various types of materials including sheet metal, tile, sandwich panel or asphalt membrane by mechanical fastening.

– Economically viable.

MINIMUM CONDITIONS:

– Their design and geometry must ensure safety, strength, rigidity and stability.